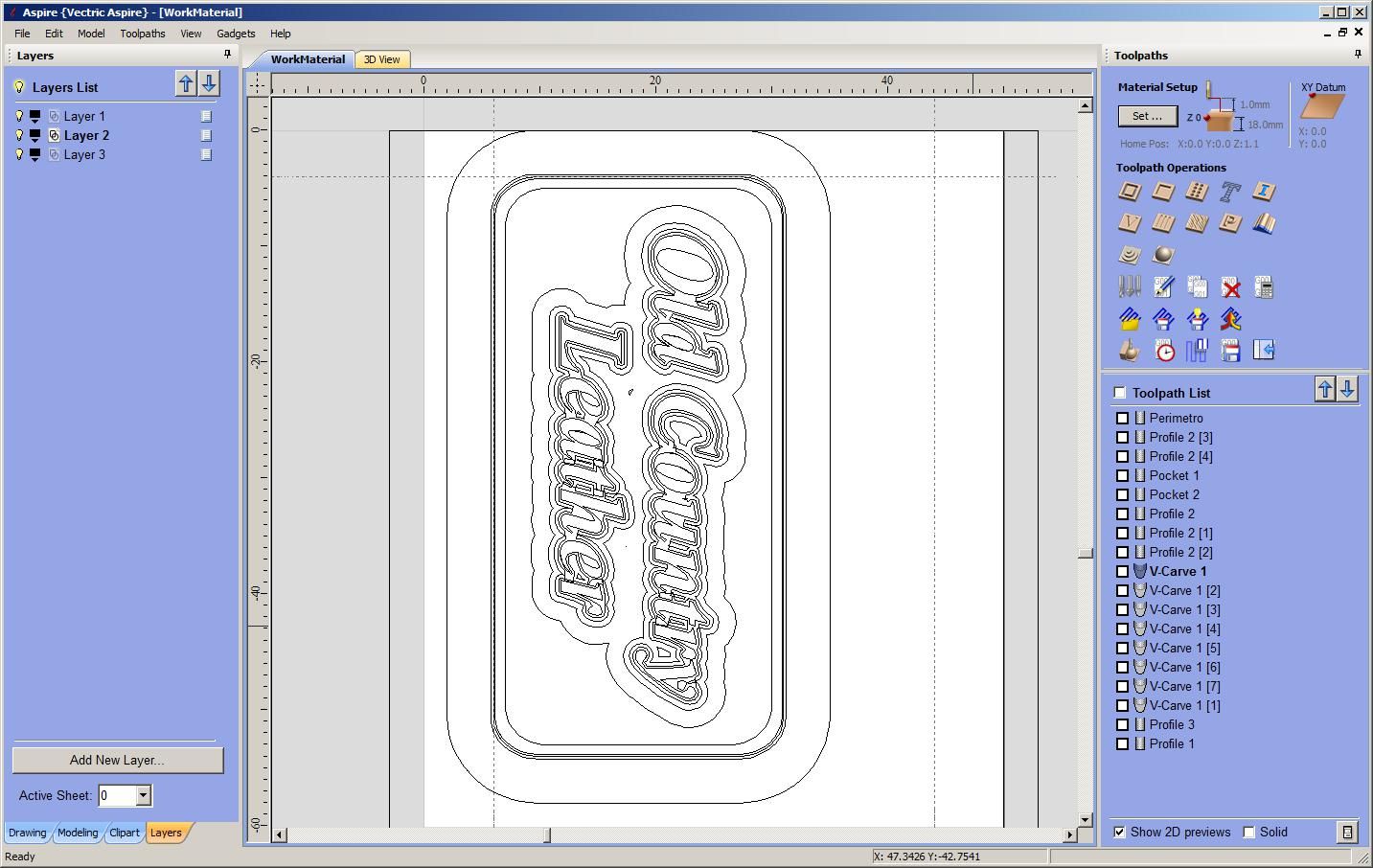

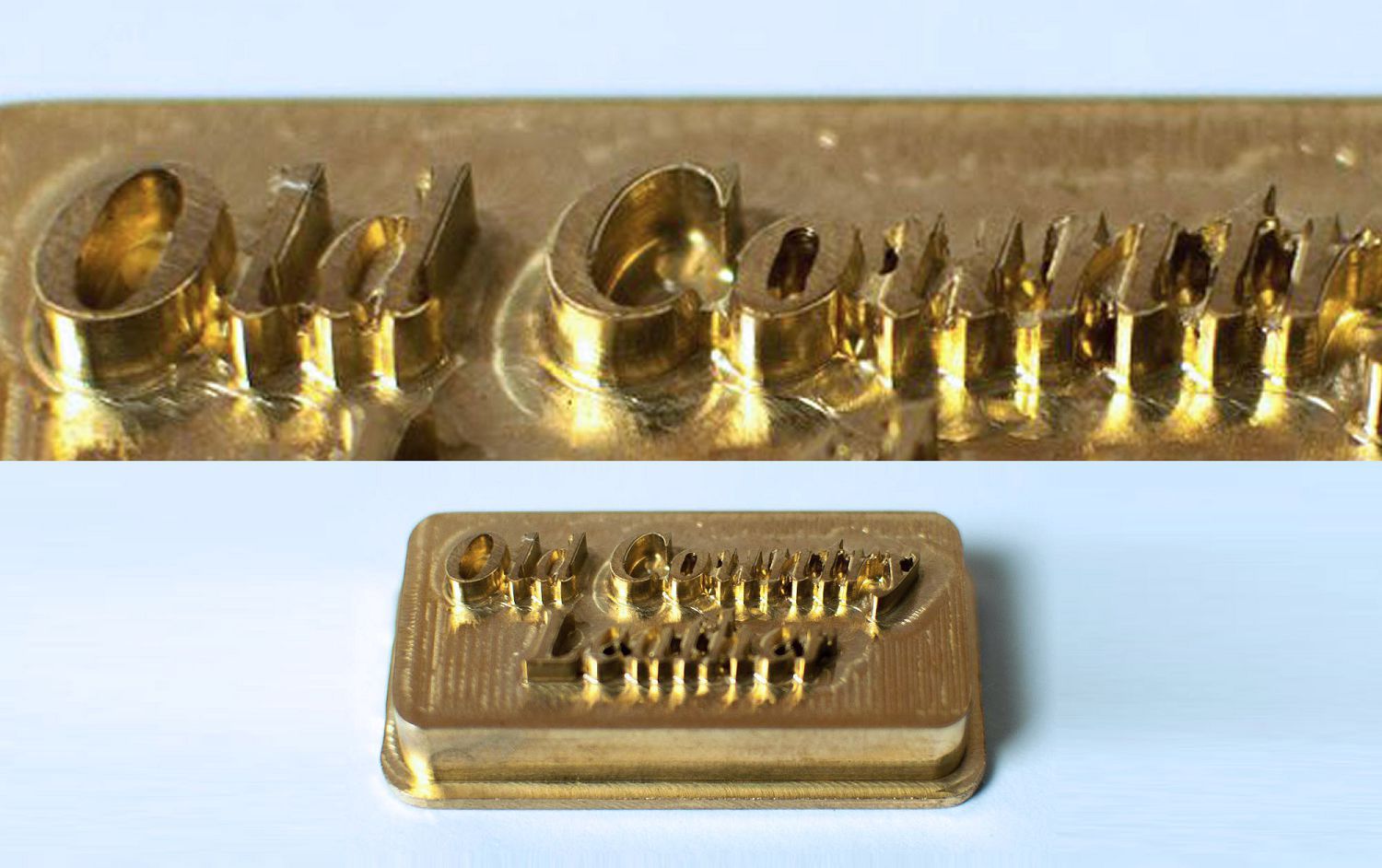

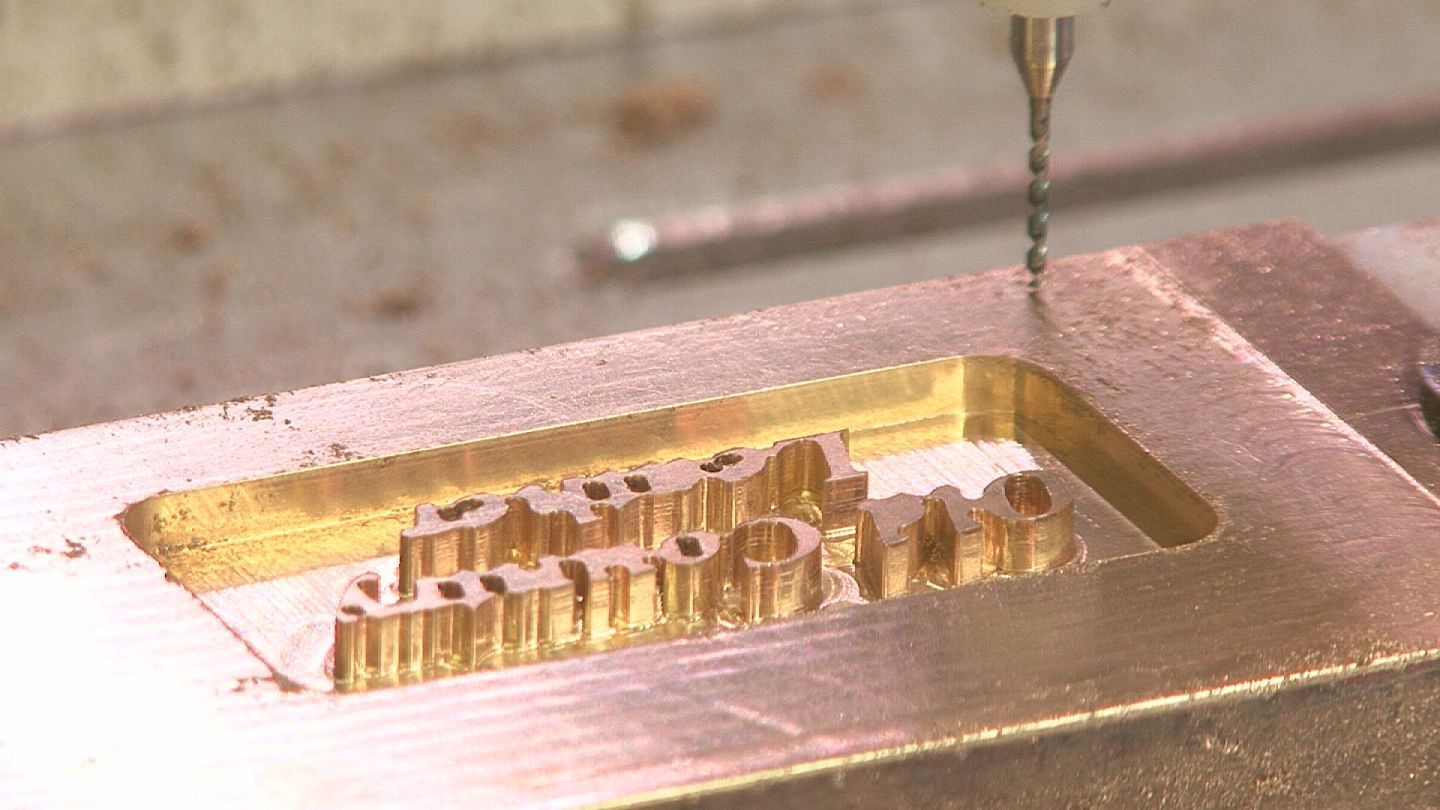

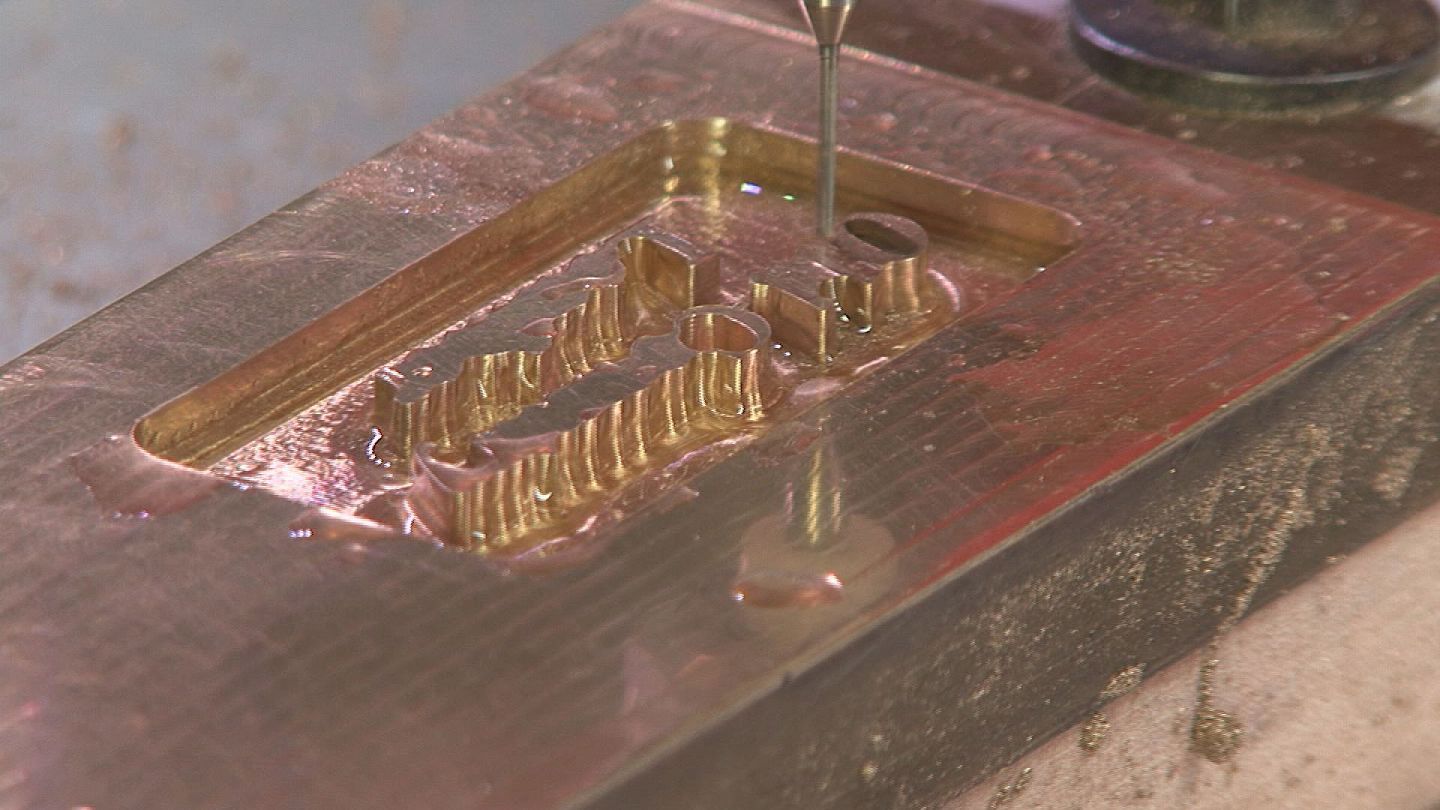

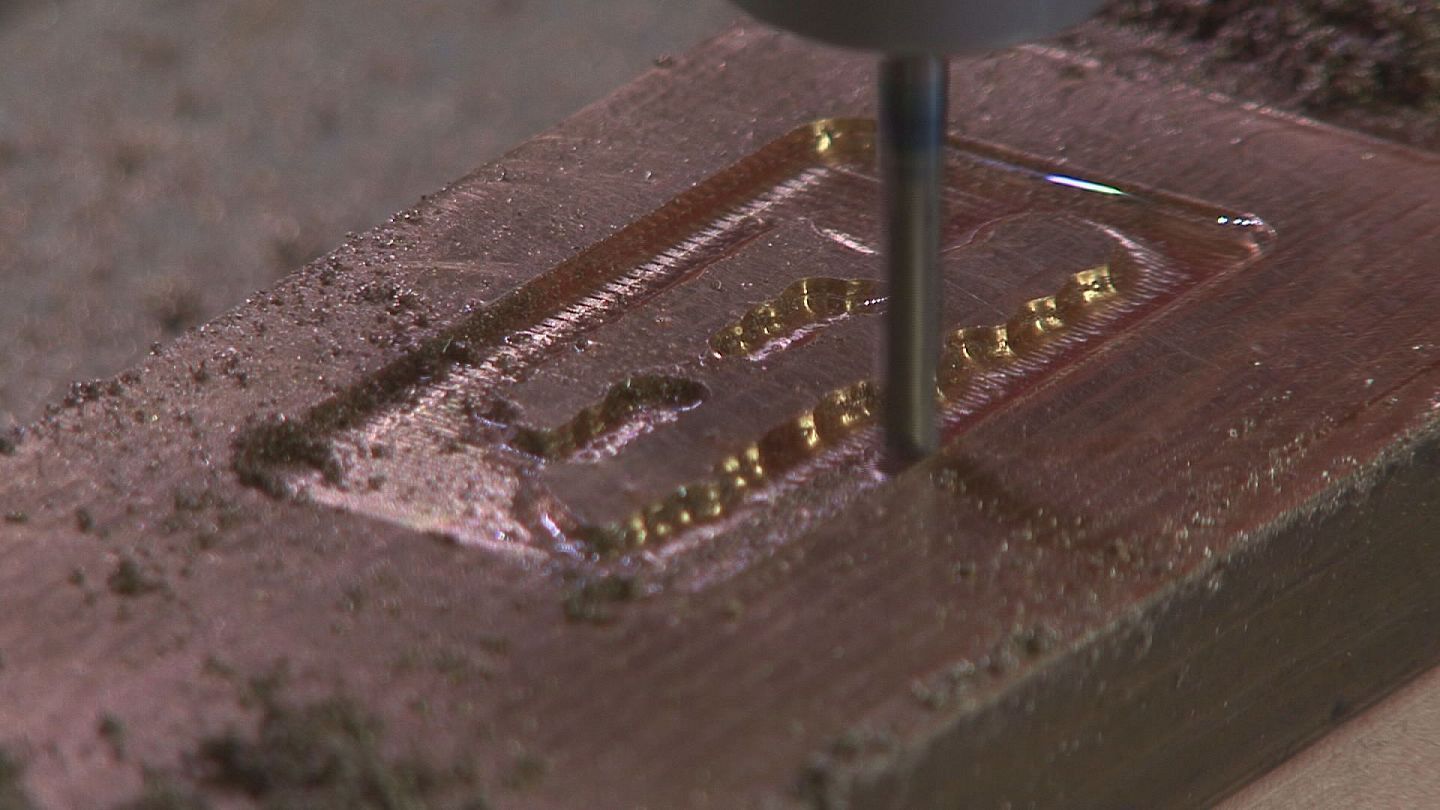

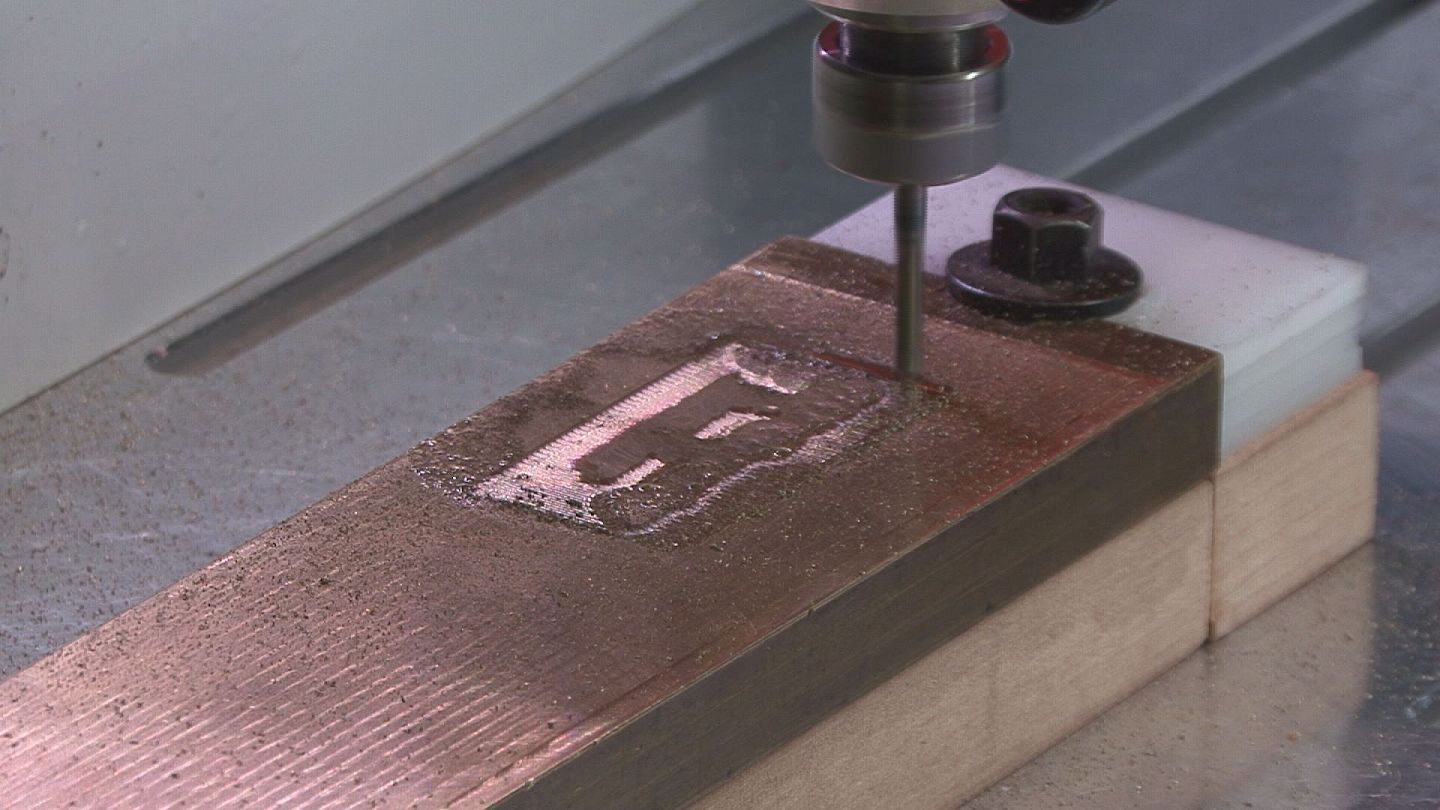

Many times people think of using a CNC router for cutting wood and plastic and not for detailed machining. This project is a small stamp made out of brass that you head up and then press into material such as leather. Due to the fine detail, the job had to be machined with 5 separate end mills each getting progressively smaller. Keep in mind that with such small tools you have to be extra careful with speeds and feeds so you get a good finish and you don't break end mills. The wall thickness on some of these letters is only 0.1mm thick... So it takes some patience and a good understanding of the tool path programming to ensure success.

The end mills and feed and speed settings used on this job are as follows:

STEP 1 - Flattening The Surface

Cutting Tool - ¼" End Mill

Pass Depth: 0.1mm

Stepover: 15%

Speed: 11,000 RPM

Feed Rate: 8mm/sec

Plunge Rate: 5mm/sec

Final Cut Depth: 0.3mm

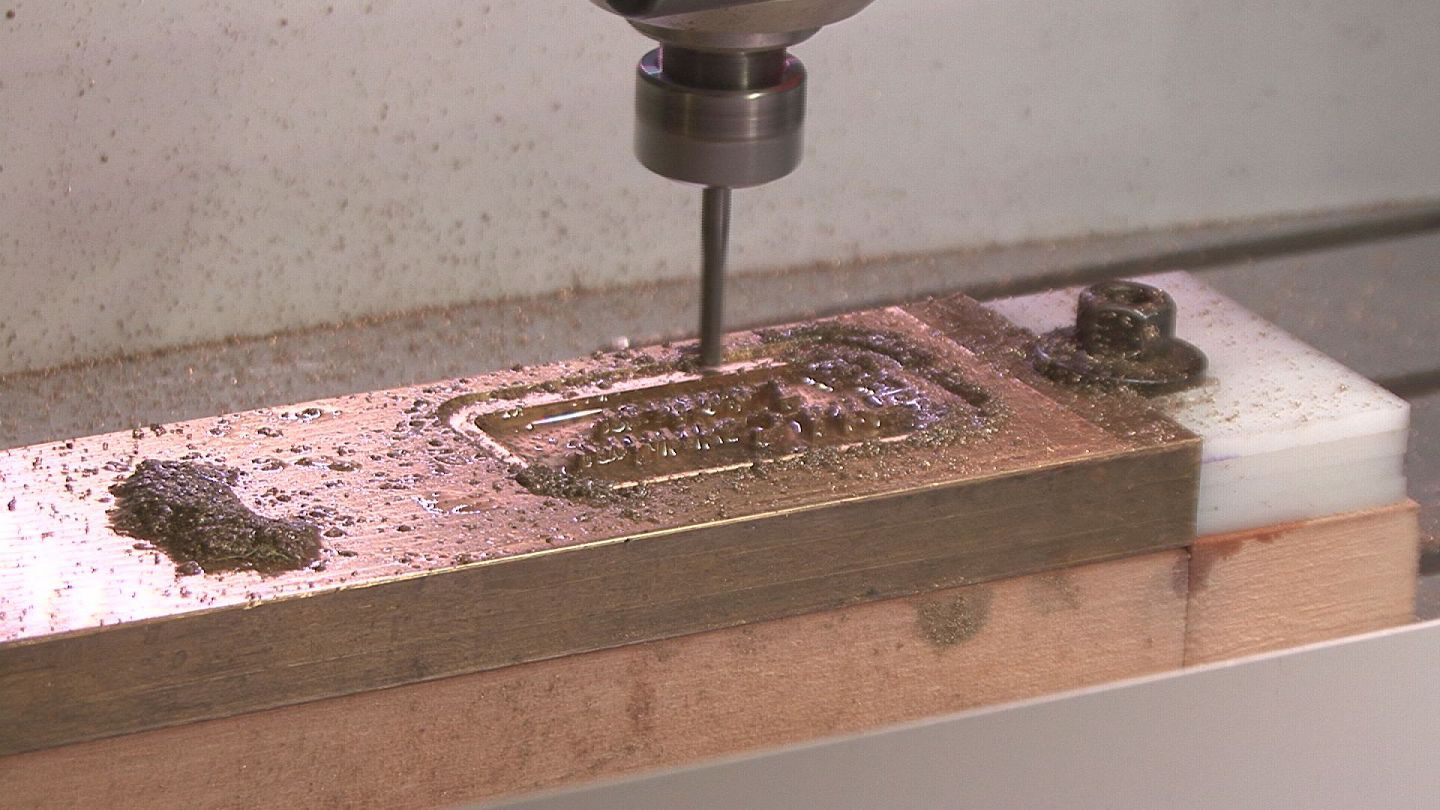

STEP 2 - First Pocket

Cutting Tool - 1/8" End Mill

Pass Depth: 0.1mm

Stepover: 15%

Speed: 11,000 RPM

Feed Rate: 6mm/sec

Plunge Rate: 3mm/sec

Final Cut Depth: 3mm

NOTE: This tool path makes a small outline of the logo to get the end mill closer without touching the text.

STEP 3 - First Profile Tool Path For Details

Cutting Tool: 2mm End Mill

Pass Depth: 0.1mm

Stepover: 30%

Speed: 11,000 RPM

Feed Rate: 4mm/sec

Plunge Rate: 2mm/sec

Final Cut Depth: 3mm

NOTE: This tool path is the same as STEP 2 but slightly closer to the final vectors.

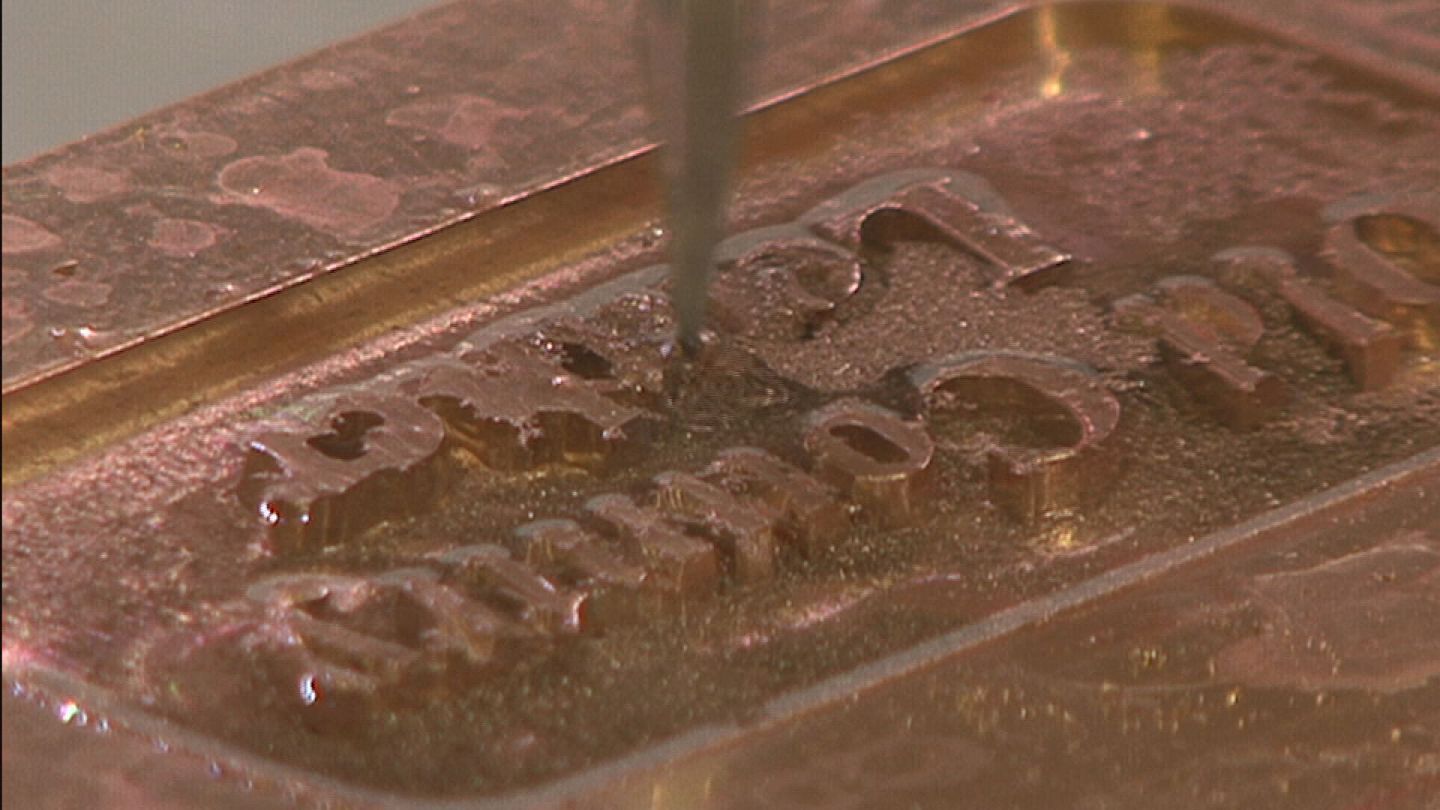

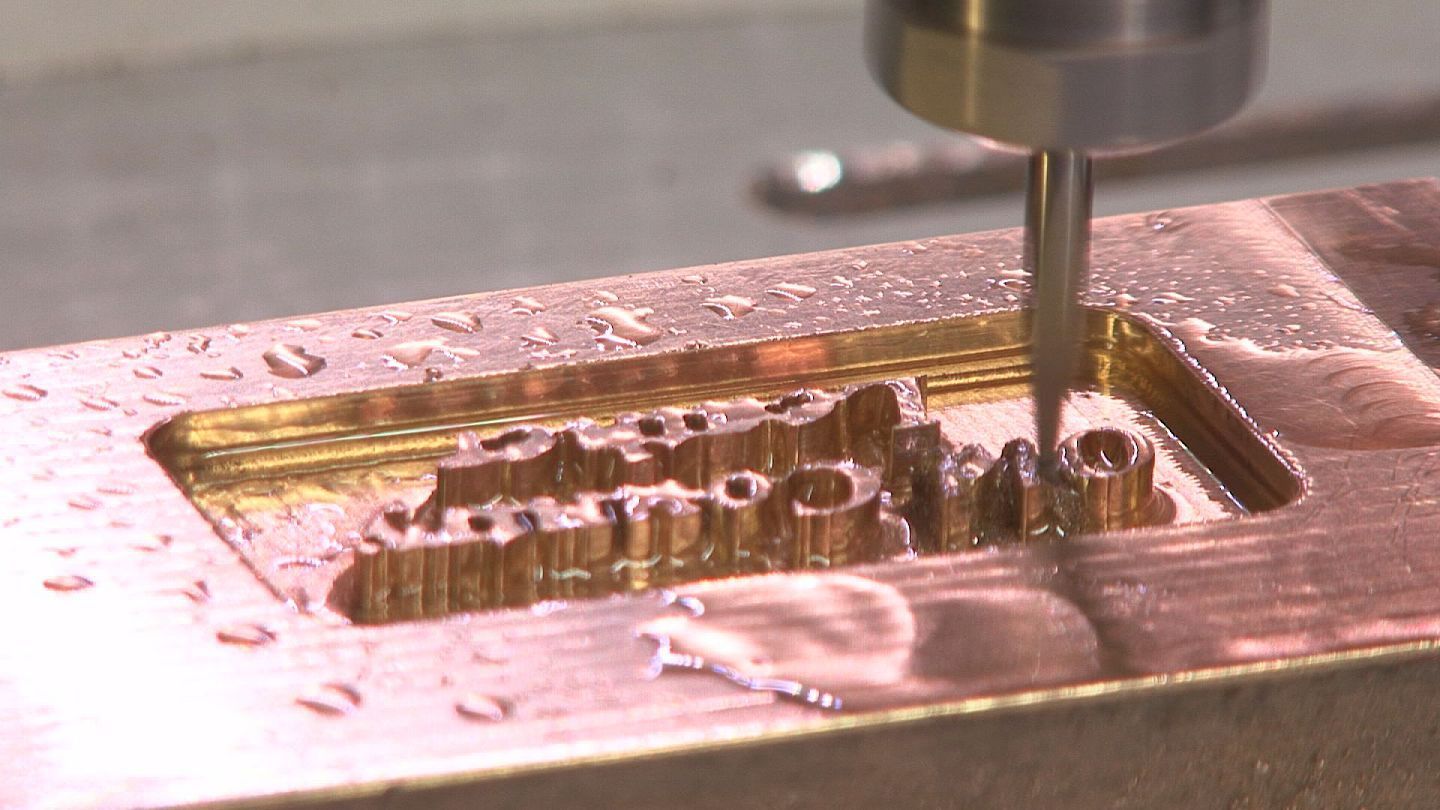

STEP 4 - Second Pass For More Details

Cutting Tool: 1mm End Mill

Pass Depth: 0.06mm

Stepover: 15%

Speed: 11000 RPM

Feed Rate: 2mm/sec

Plunge Rate: 2mm/seg

Final Cut Depth: 3mm

All the way to the text

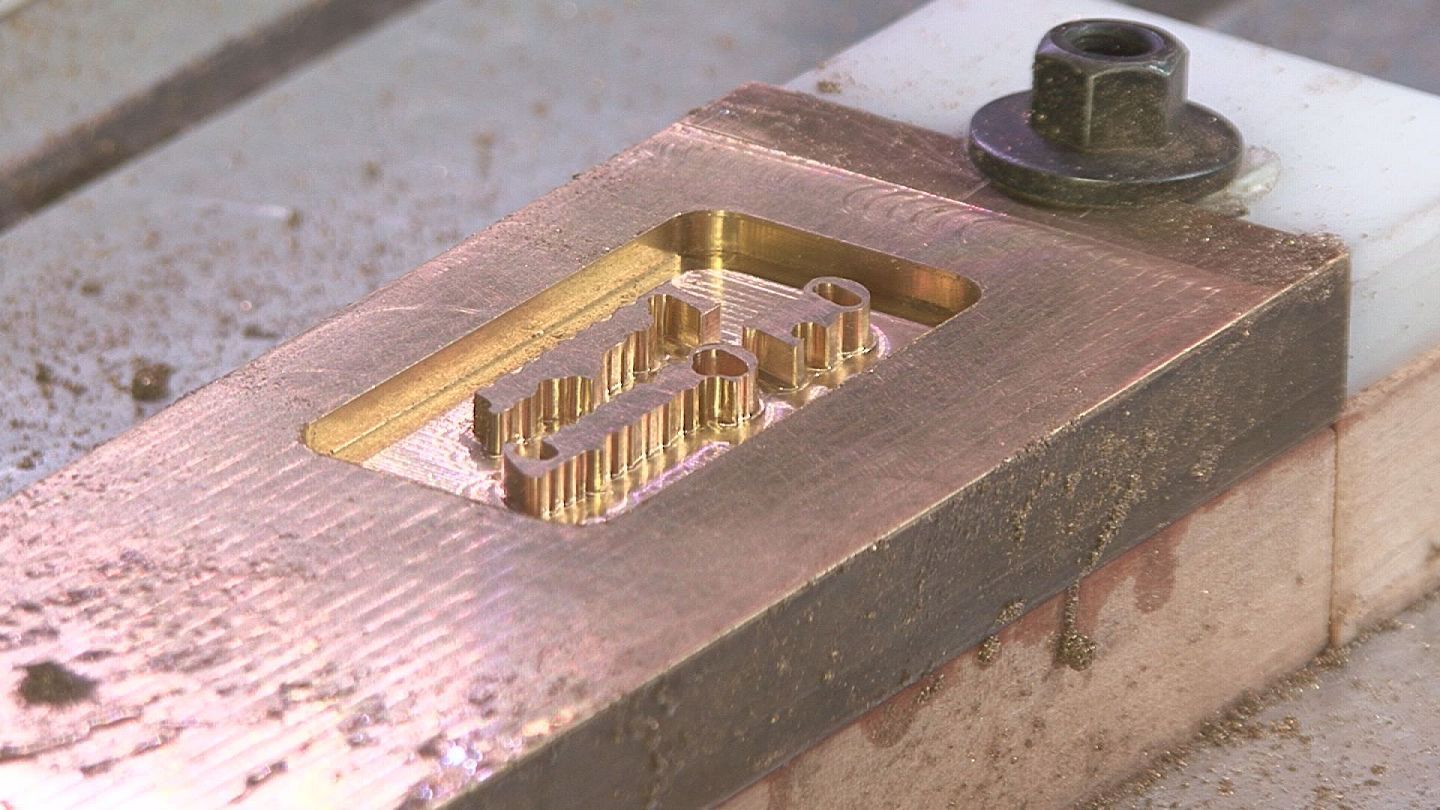

STEP 5 - Final Detail Pass Removing Last 1mm

Cutting Tool: 15 degree V-Bit with

1/8 shank and 0.1mm Tip RadiusPass Depth: 0.05mm

Stepover: 4.5%

Clearance Pass Stepover: 10%

Speed: 11000 RPM

Feed Rate: 4mm/sec

Plunge Rate: 2mm/sec

Final Cut Depth: 1mm

NOTE: This tool path contains all outlines of the text to obtain all the details.

STEP 6 - Final cut made with the 1/8" end mill again, same settings

Cut with a pocket ½ diameter more of the end mill and final 1mm direct profile with tabs

Leather Hot Stamp Made From Brass On A Desktop CNC