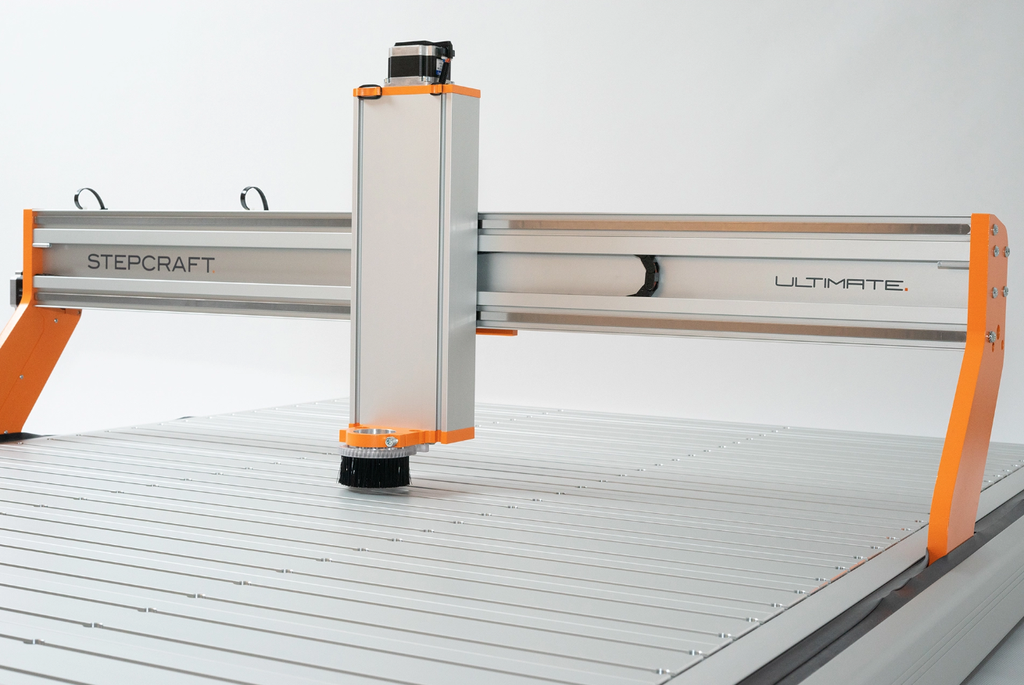

STEPCRAFT M.1400 ULTIMATE CNC System

The ULTIMATE Benchtop CNC System!

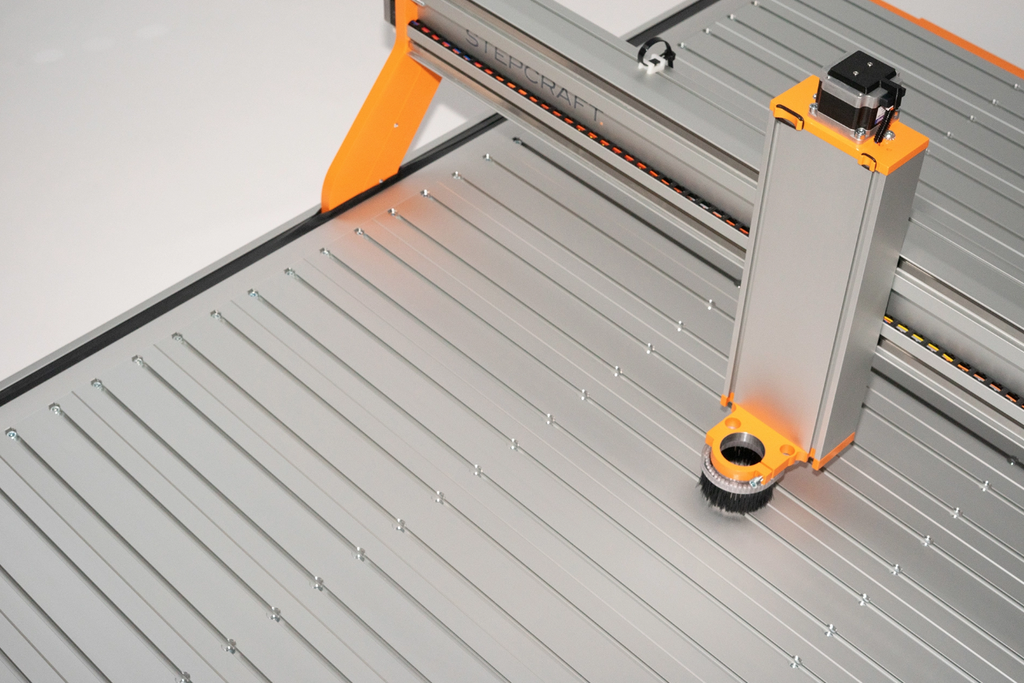

More than a CNC machine, it's the ULTIMATE CNC machine! With an impressive work area of 38.5" x 56.8" that gives you 2200 sq/in of usable surface for your projects and jobs. Add to that an impressive Z-travel of 7.6" and the ability to have over 9.75" of Z clearance if you move the table to the lower position and you can start to see why the M.1400 deserves the "ULTIMATE" title.

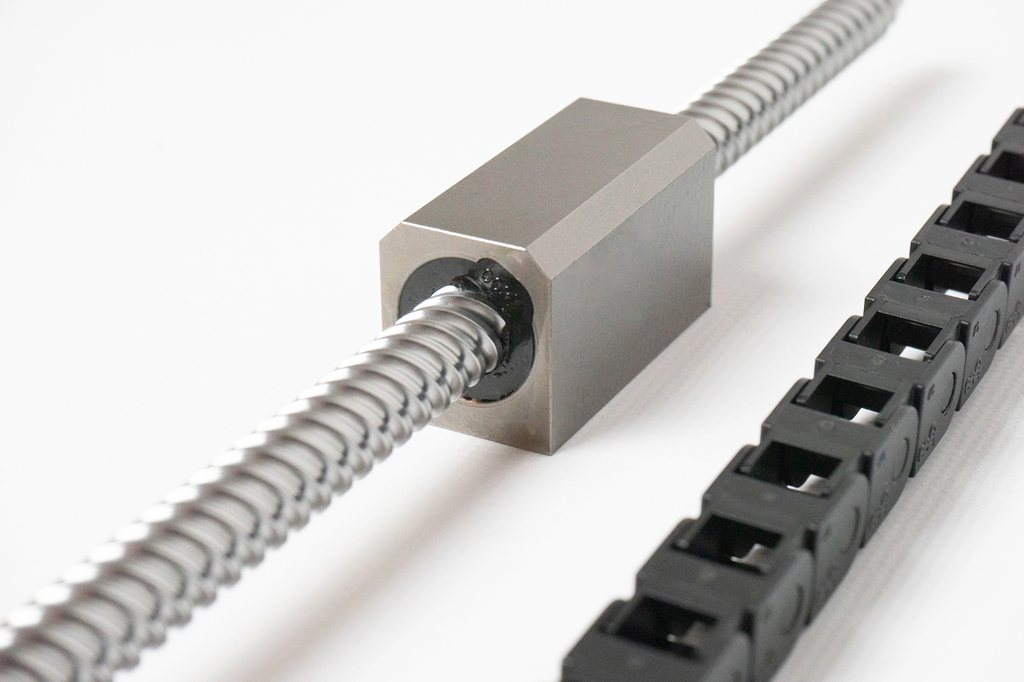

Everything has been upgraded on the M.1400: the largest M.Series work surface yet, larger and more powerful 4 amp Sanyo Denki NEMA 23 motors on the X and Y axes, genuine HIWIN ball screws on all axes, the Semi-Closed Loop motor drive system is included, Bosch Rexroth precision linear rails on all axes, comes standard with an aluminum T-Slot table and you can optionally add a Vacuum Table to the machine. The M.1400 runs over 40% faster than the other machines in the M-Series lineup, with a whopping 400 in/min (170 mm/sec) travel speed, so you can not only work on much larger projects but you can get them done faster too!

It's The Ultimate M!

The M.1400 still has all of the industry-first features that make the M-Series line of CNC Systems stand out from the pack. With features like, Freestyle Milling, two different machine table levels, fully encapsulated wiring for a clean work area, optional vertical milling, optional Automatic Tool Changer, and much more. The STEPCRAFT M-Series line of CNC systems offers you unprecedented freedom with the title of the most versatile CNC milling machine in the world.

With the STEPCRAFT M.1400, you can easily process large sheets of material, floors, or even existing furniture. You can let your creativity run free because all tools that are compatible with the D-Series can also be used on the STEPCRAFT M-Series. You can use the system for milling, cutting, carving, 3D printing, laser engraving, and much more. The STEPCRAFT M-Series is perfect for workshops, job sites, schools, and production facilities.

INDUSTRY-LEADING CNC TECHNOLOGY

Our German-Engineered CNC technology gives you high-precision results. The STEPCRAFT M-Series offers precision, durability and reliability often only found in industrial machines thanks to the innovative extruded profiles and the Bosch Rexroth linear guides. We have gone to great lengths to deliver concealed cable routing on our M-Series CNC milling machines for a clean work environment so you can focus on what matters... your work! Our innovative Semi Closed Loop System™ acts as your "insurance policy", preventing lost steps and protecting your work in the event something goes wrong. This page is full of examples as to why STEPCRAFT is a world leader in benchtop CNC systems that can grow as your skills and your business grows.

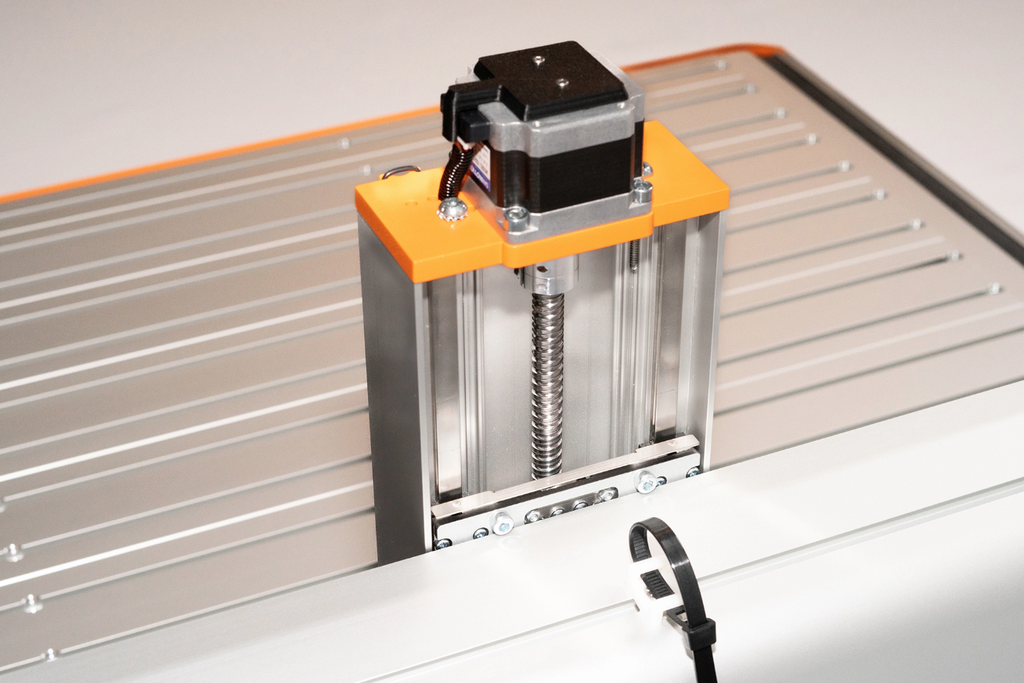

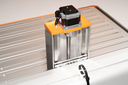

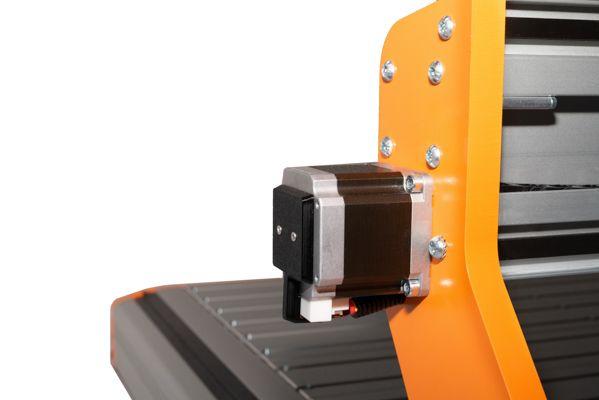

Semi Closed-Loop System™

Every STEPCRAFT M-Series machine will automatically realign the gantry after each reference run when homing the machine. The optional Semi-Closed Loop System gives you the additional insurance of step monitoring in your CNC system. If the system detects a deviation from predefined steps from any motor, such as in the event of a crash or incorrect settings, the emergency stop is triggered automatically and your workpiece is protected. Then you simply correct the error, reference the machine and continue your job where you left off.

Precision Linear Guides

Every axis of the STEPCRAFT M-Series CNC machines utilizes precision hardened linear guide rails from Bosch Rexroth. These recirculating ball bearing linear rails provide a high load-bearing capacity, extremely reliable performance with no wear. A special seal is built into every bearing carriage to protect the linear guide system from dust and debris, giving you a reliable, virtually maintenance-free CNC guide system. German-based Bosch Rexroth is a global leader in the manufacturing of precision ball bearing linear guide systems. Only the finest components are used in the STEPCRAFT M-Series CNC machines which gives you high performance and a very accurate CNC system.

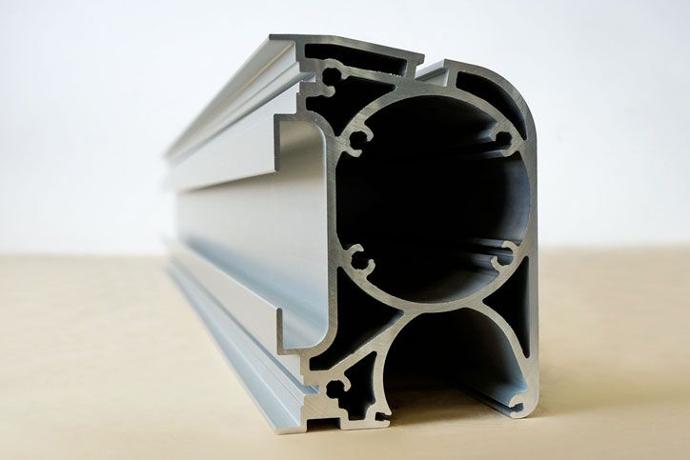

Highly Stable Frame Profiles

The frame profiles are one of many areas where STEPCRAFT really excels and is constantly setting new standards with regards to the stability and design of CNC machines. The custom extruded frame profiles are the result of countless hours of design engineering and testing utilizing the best in CAD/CAM and analysis software. These design elements create a high force absorption and even distribution of the forces within the axis. An extremely high torsional stiffness is achieved this way. The STEPCRAFT frame profiles offer a level of stability that is not possible with steel.