M.500 ATC Tool Magazine w/Dust Boot Control

Description

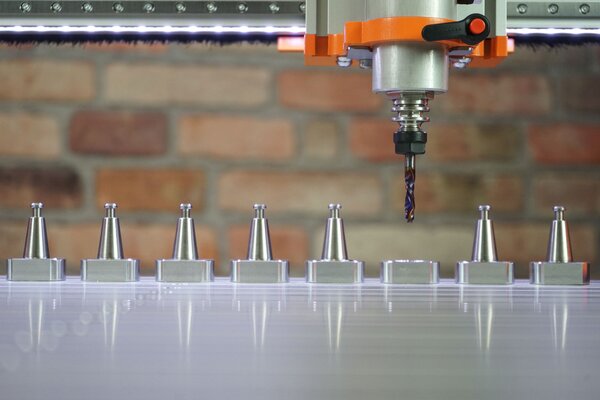

The new Tool Magazine for the STEPCRAFT M-Series makes working with the Automatic Tool Changer even more convenient! With up to ten tool holders, the Tool Magazine offers plenty of space for a wide variety of end mills. Two retaining rings for SK15 tool holders are already pre-assembled, additional ones are optionally available. Thanks to the integrated tool length sensor, the length of the different end mills can be determined quickly and automatically.

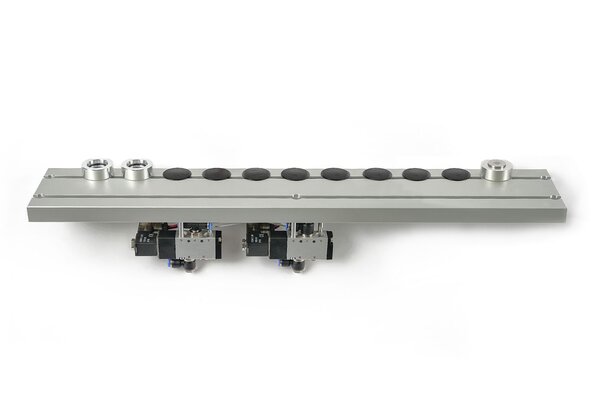

Additionally, the Tool Magazine features an innovative, pneumatic lifting mechanism for the simultaneous use of the Exhaust Adapter and Automatic Tool Changer. When a tool is picked up or put down, the Exhaust Adapter automatically moves upwards clearing the way for the change of tool. This makes milling even more clean and efficient. The speed of the lifting mechanism can be individually adjusted via a throttle. Furthermore, the metal connector of the Exhaust Adapter can be held permanently in the highest position.

The Tool Magazine is delivered as a partially assembled module and simply inserted in the place of the last table panel (MDF or aluminum). With the help of the enclosed plugs, unused tool slots can be easily closed and, thus, protected against dust and debris. The Tool Magazine is connected to the mainboard of the STEPCRAFT M-Series and to compressed air. For this purpose, a compressor is required with at least 9-10 bar that is not included in the scope of delivery.

Technical Specifications:

- Up to 7 tool holders possible

- Pneumatic lifting mechanism for simultaneous use of Exhaust Adapter and Automatic Tool Changer

- Low installation height of only approx. 1,4 cm

- Integrated machine table solution

- Only suited for use with the Automatic Tool Changer MM-1000/KRESS/AMB

- For STEPCRAFT M-Series

Scope of Delivery:

- Tool Magazine, partially assembled

- Pneumatic lifting mechanism for Exhaust Adapter

- Integrated Tool Length Sensor

- 2x Retaining ring for SK 15 tool holder

- 8x Plugs for closing unused tool slots

The new Tool Magazine for the STEPCRAFT M-Series makes working with the Automatic Tool Changer even more convenient! With up to ten tool holders, the Tool Magazine offers plenty of space for a wide variety of end mills. Two retaining rings for SK15 tool holders are already pre-assembled, additional ones are optionally available. Thanks to the integrated tool length sensor, the length of the different end mills can be determined quickly and automatically.

Additionally, the Tool Magazine features an innovative, pneumatic lifting mechanism for the simultaneous use of the Exhaust Adapter and Automatic Tool Changer. When a tool is picked up or put down, the Exhaust Adapter automatically moves upwards clearing the way for the change of tool. This makes milling even more clean and efficient. The speed of the lifting mechanism can be individually adjusted via a throttle. Furthermore, the metal connector of the Exhaust Adapter can be held permanently in the highest position.

The Tool Magazine is delivered as a partially assembled module and simply inserted in the place of the last table panel (MDF or aluminum). With the help of the enclosed plugs, unused tool slots can be easily closed and, thus, protected against dust and debris. The Tool Magazine is connected to the mainboard of the STEPCRAFT M-Series and to compressed air. For this purpose, a compressor is required with at least 9-10 bar that is not included in the scope of delivery.

Technical Specifications:

- Up to 7 tool holders possible

- Pneumatic lifting mechanism for simultaneous use of Exhaust Adapter and Automatic Tool Changer

- Low installation height of only approx. 1,4 cm

- Integrated machine table solution

- Only suited for use with the Automatic Tool Changer MM-1000/KRESS/AMB

- For STEPCRAFT M-Series

Scope of Delivery:

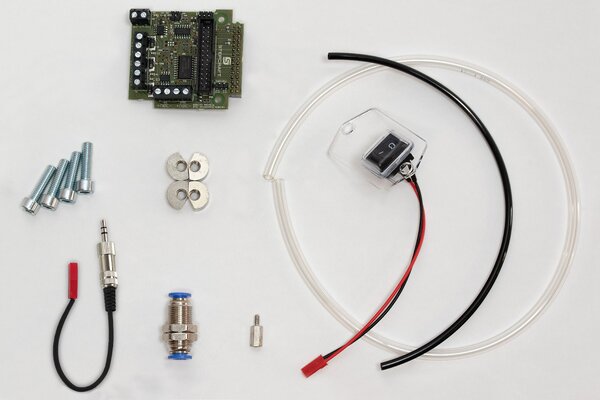

- Tool Magazine, partially assembled

- Pneumatic lifting mechanism for Exhaust Adapter

- Integrated Tool Length Sensor

- 2x Retaining ring for SK 15 tool holder

- 8x Plugs for closing unused tool slots